塗裝 顧問 團隊

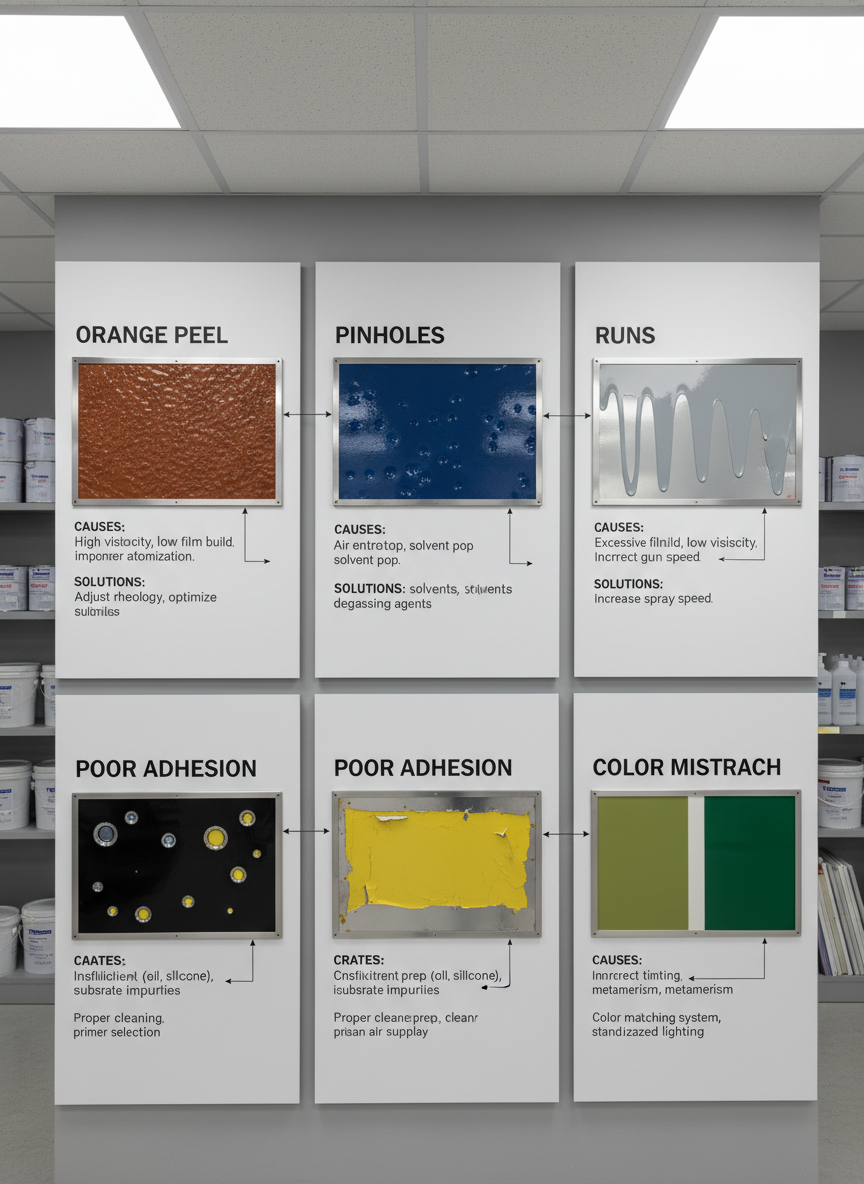

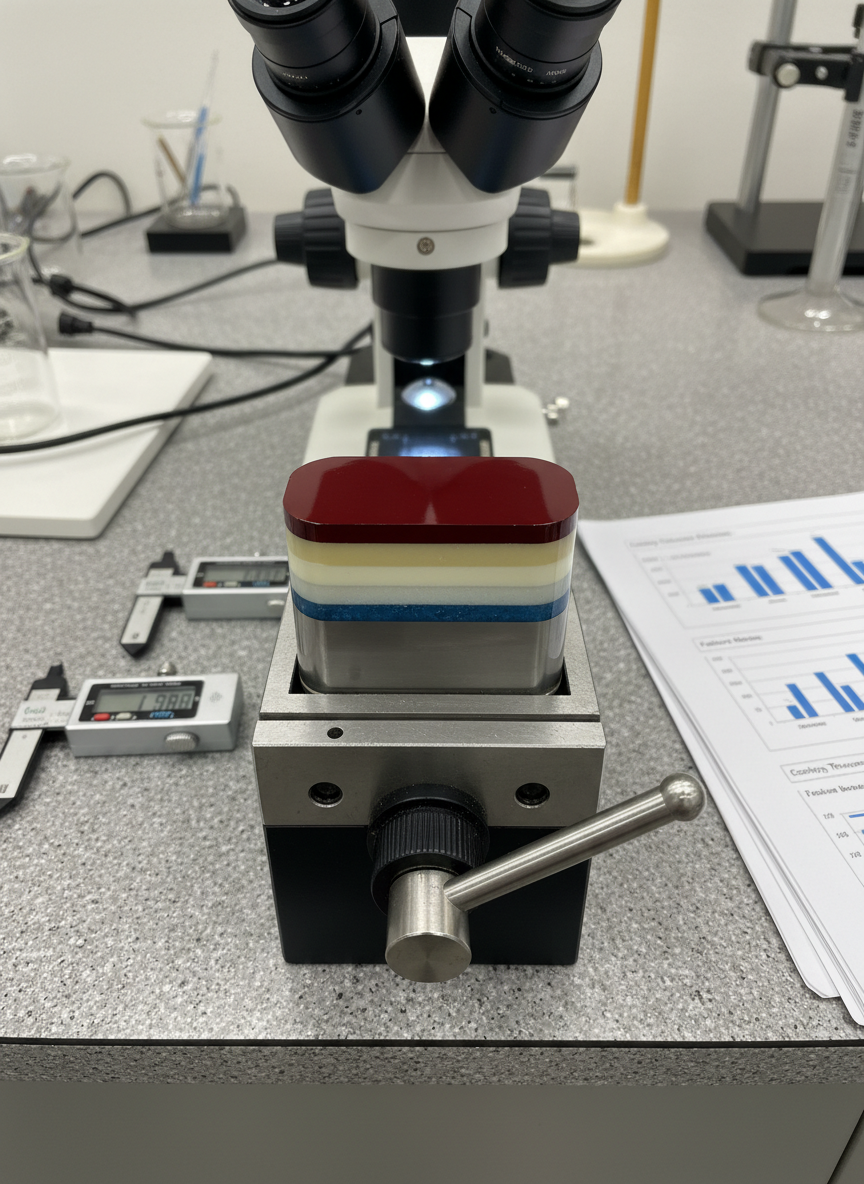

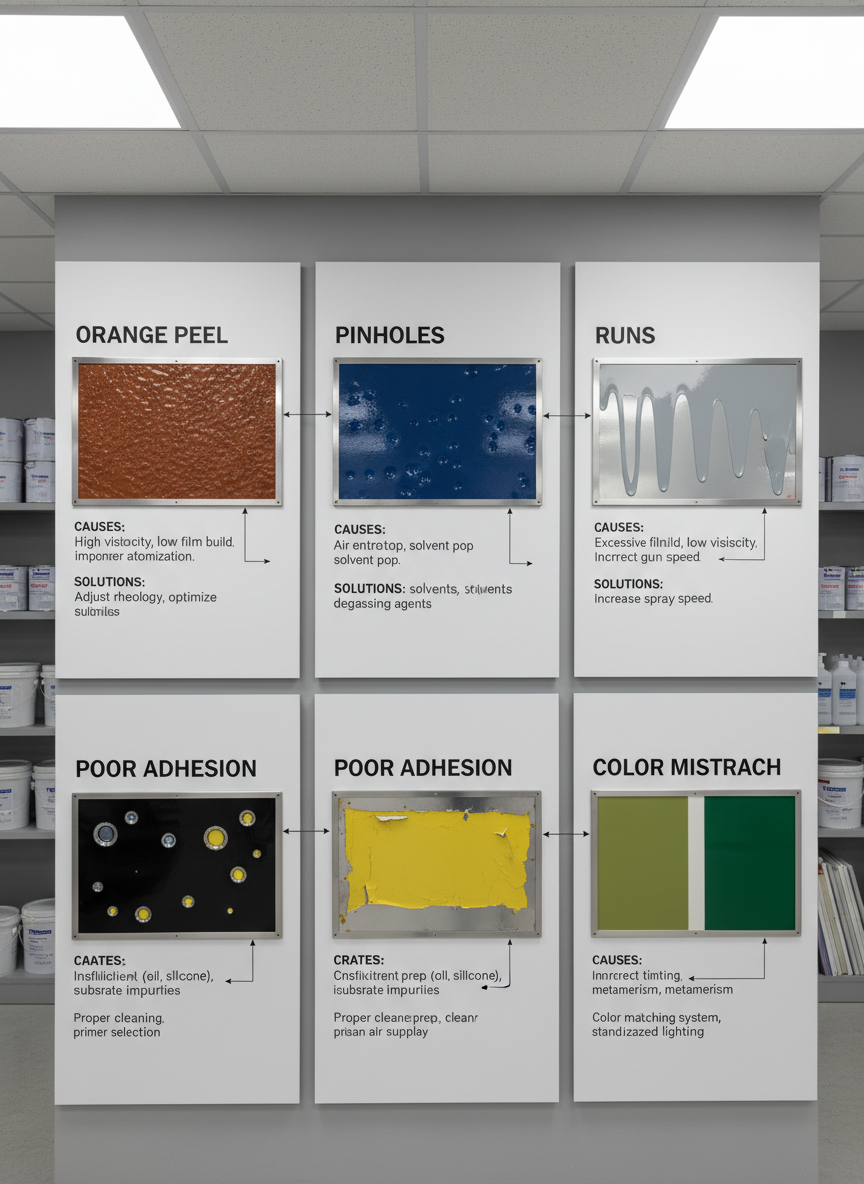

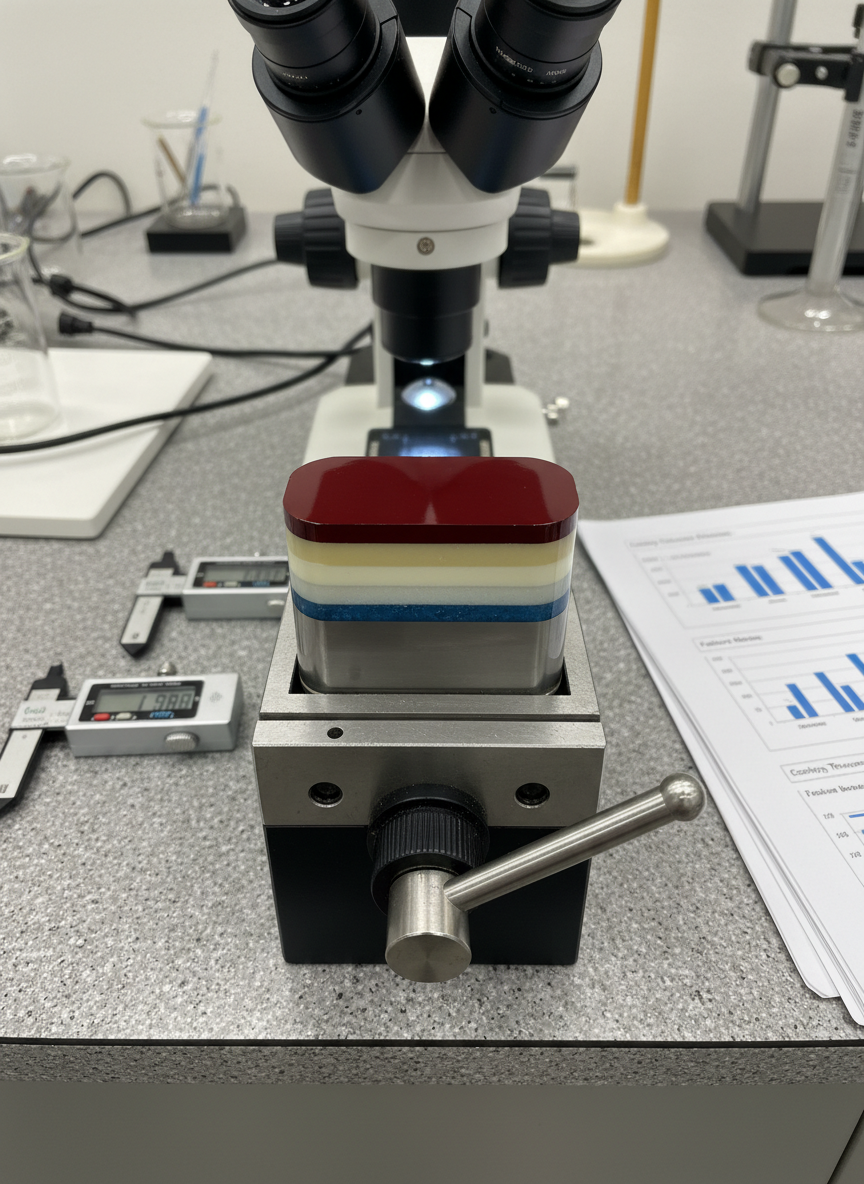

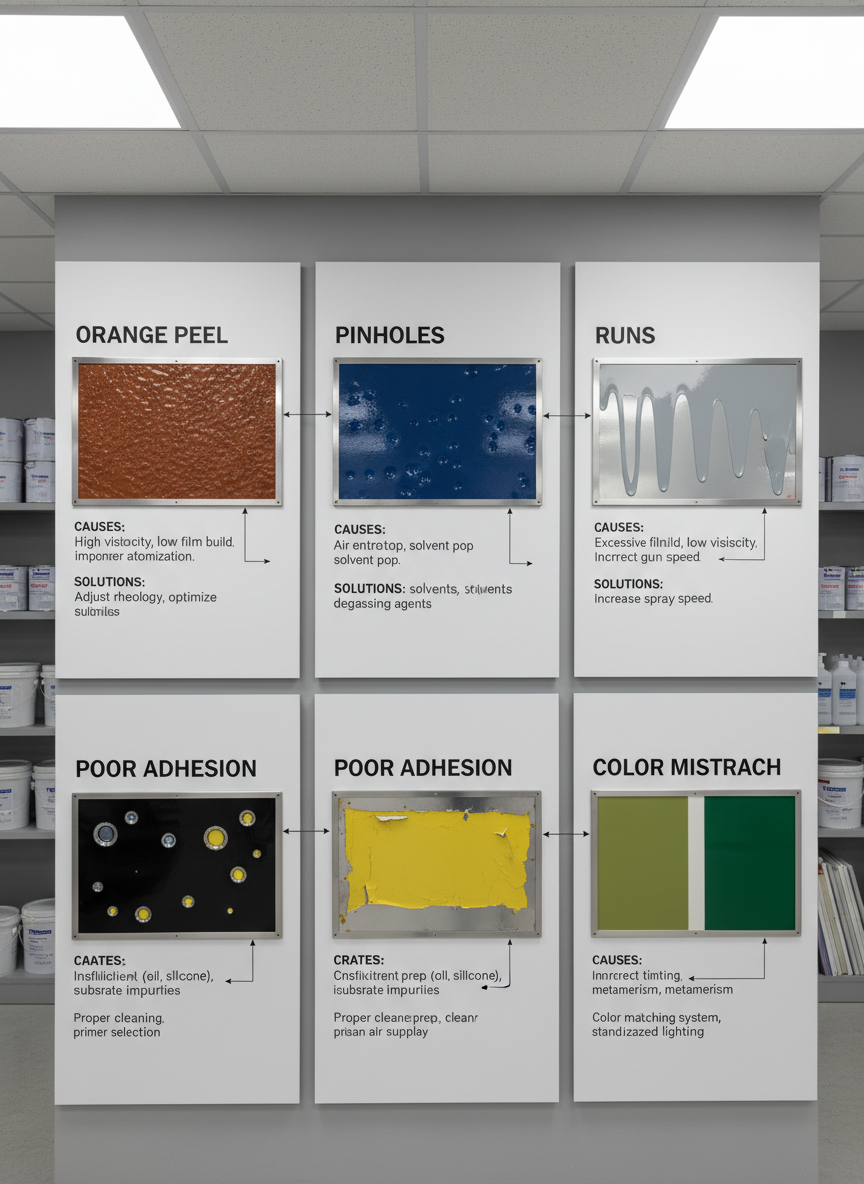

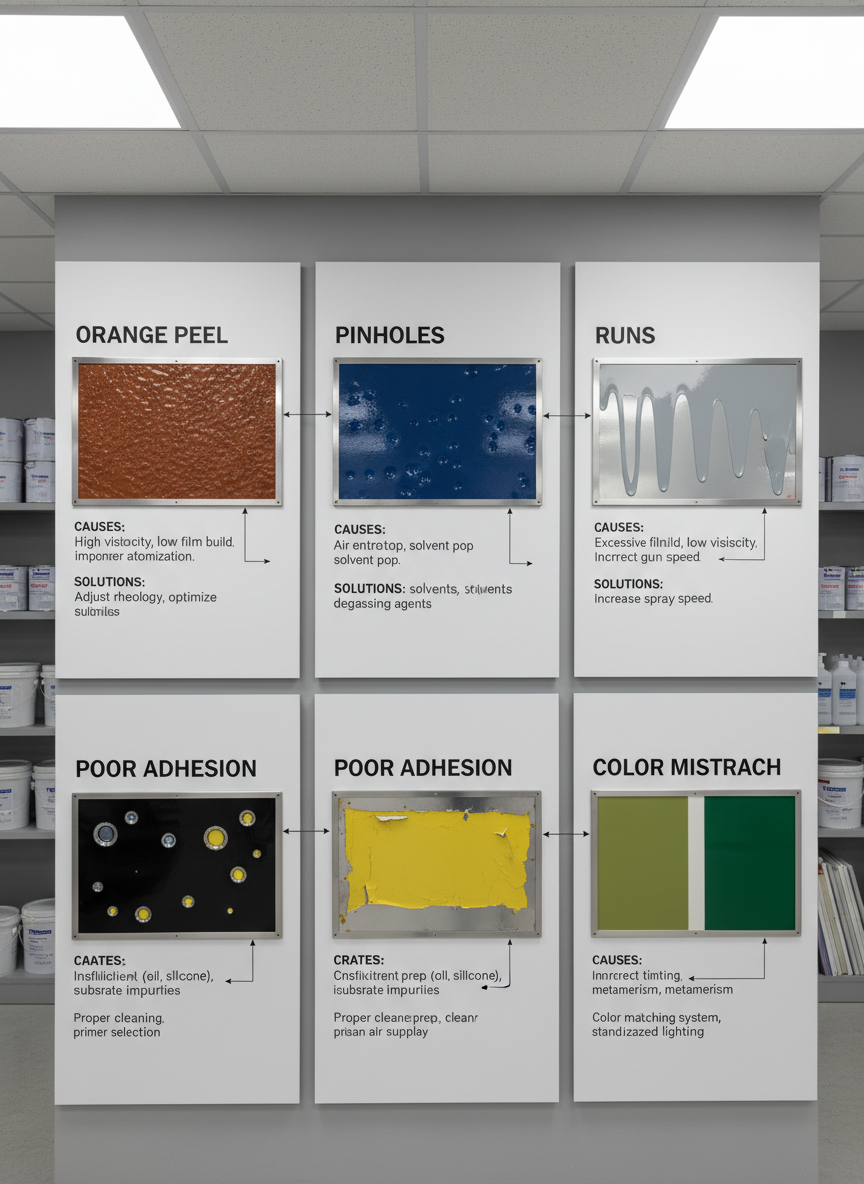

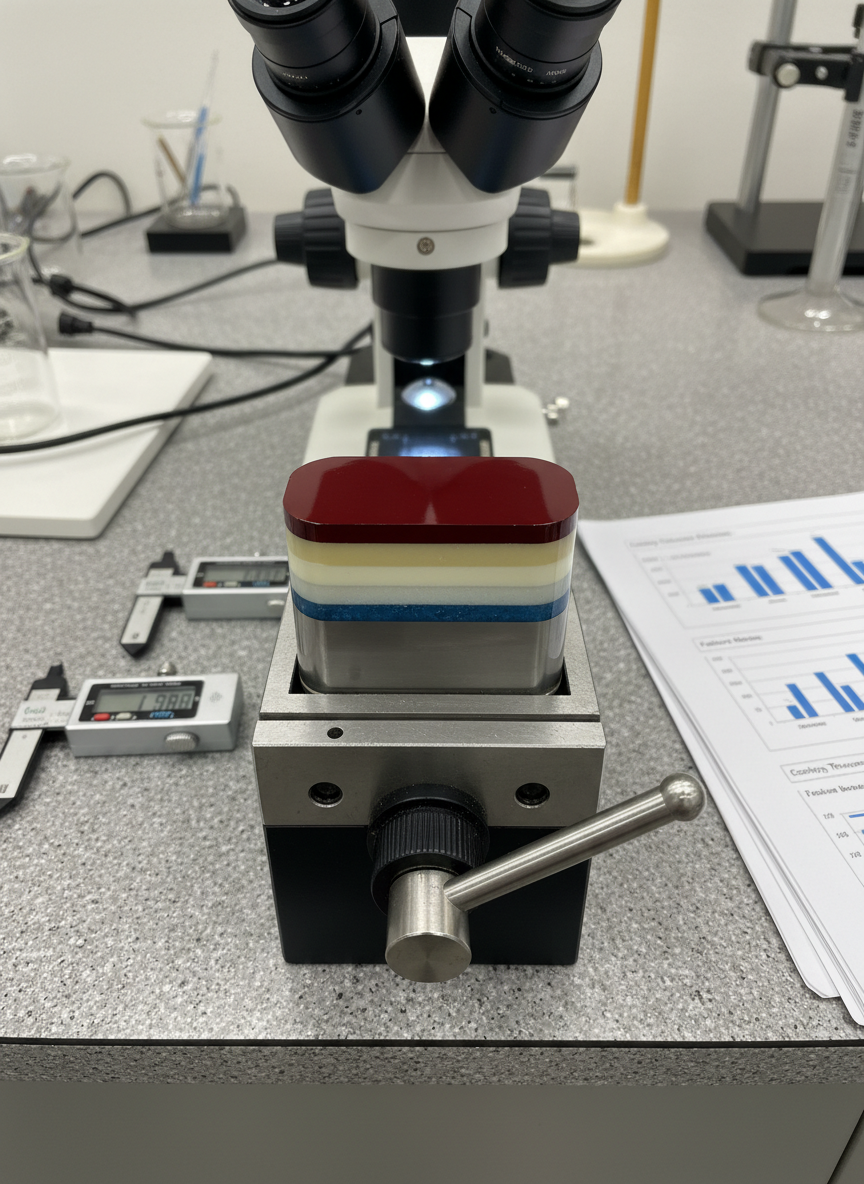

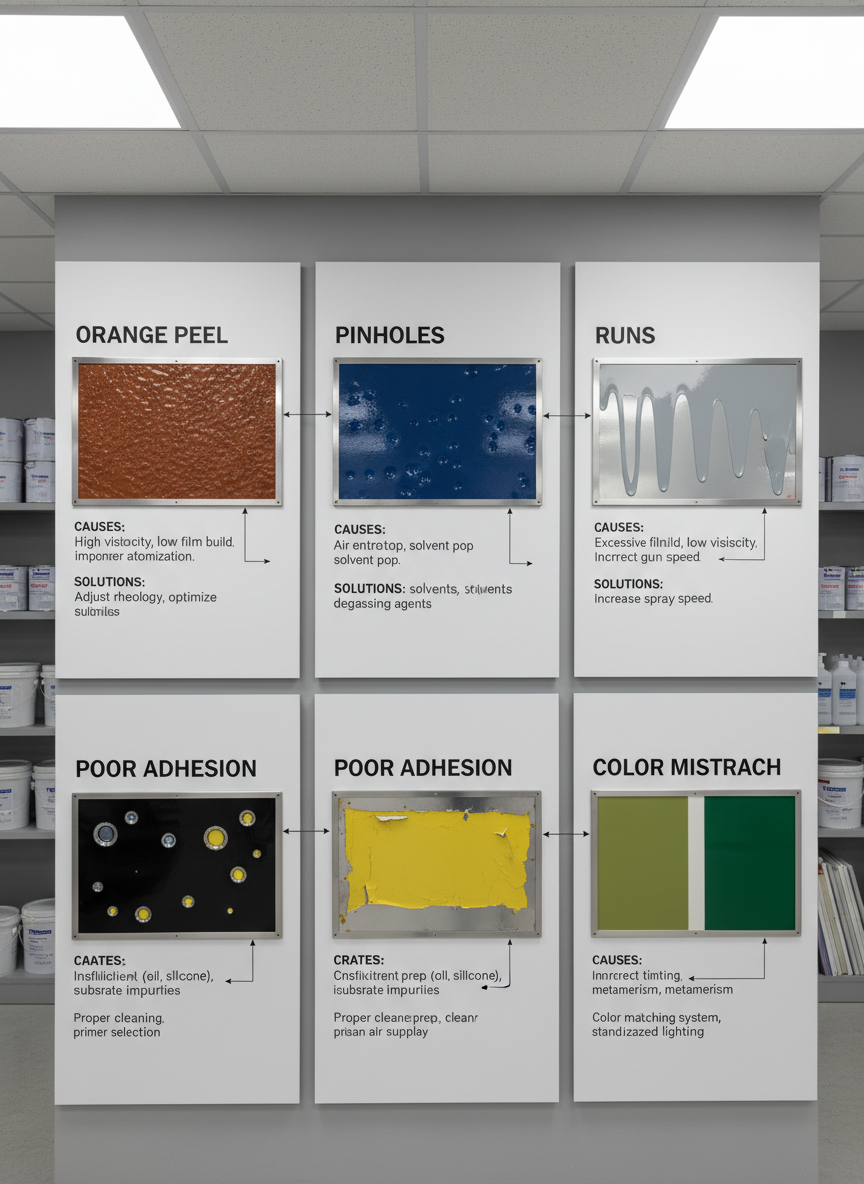

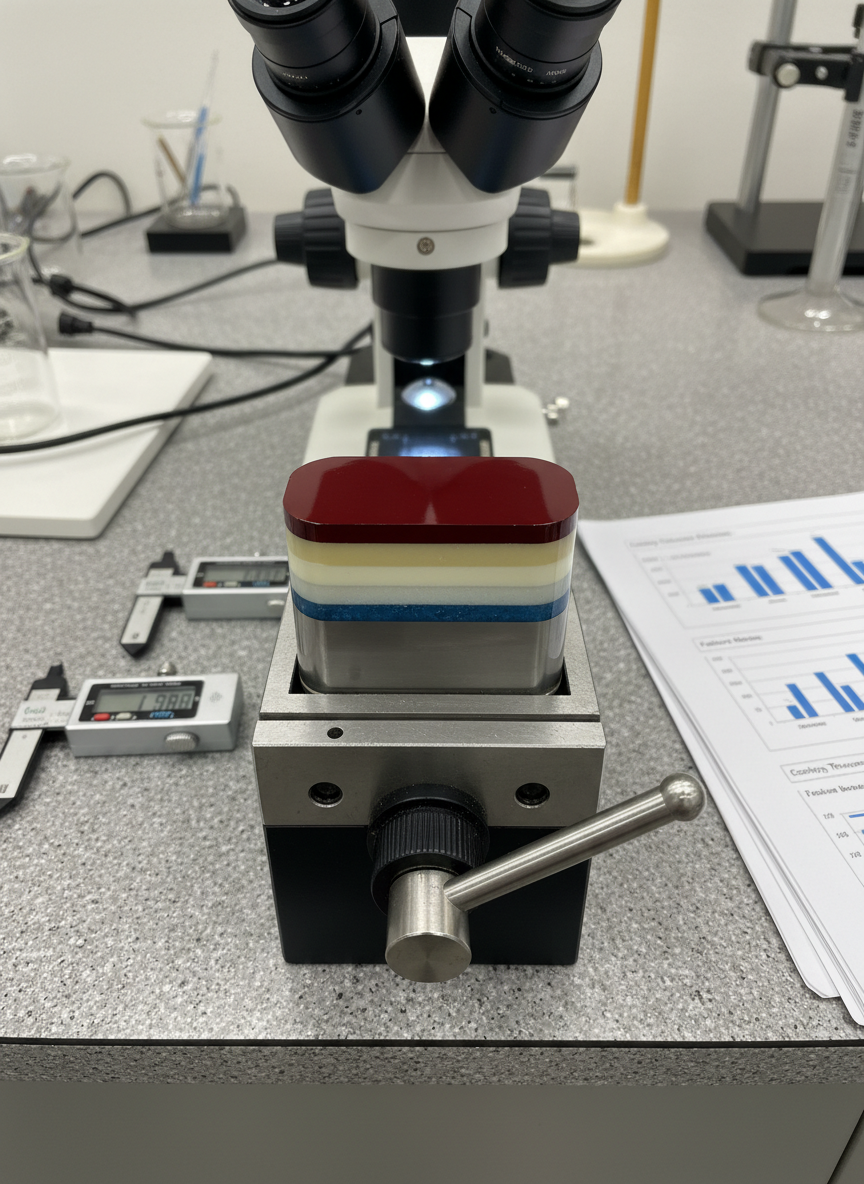

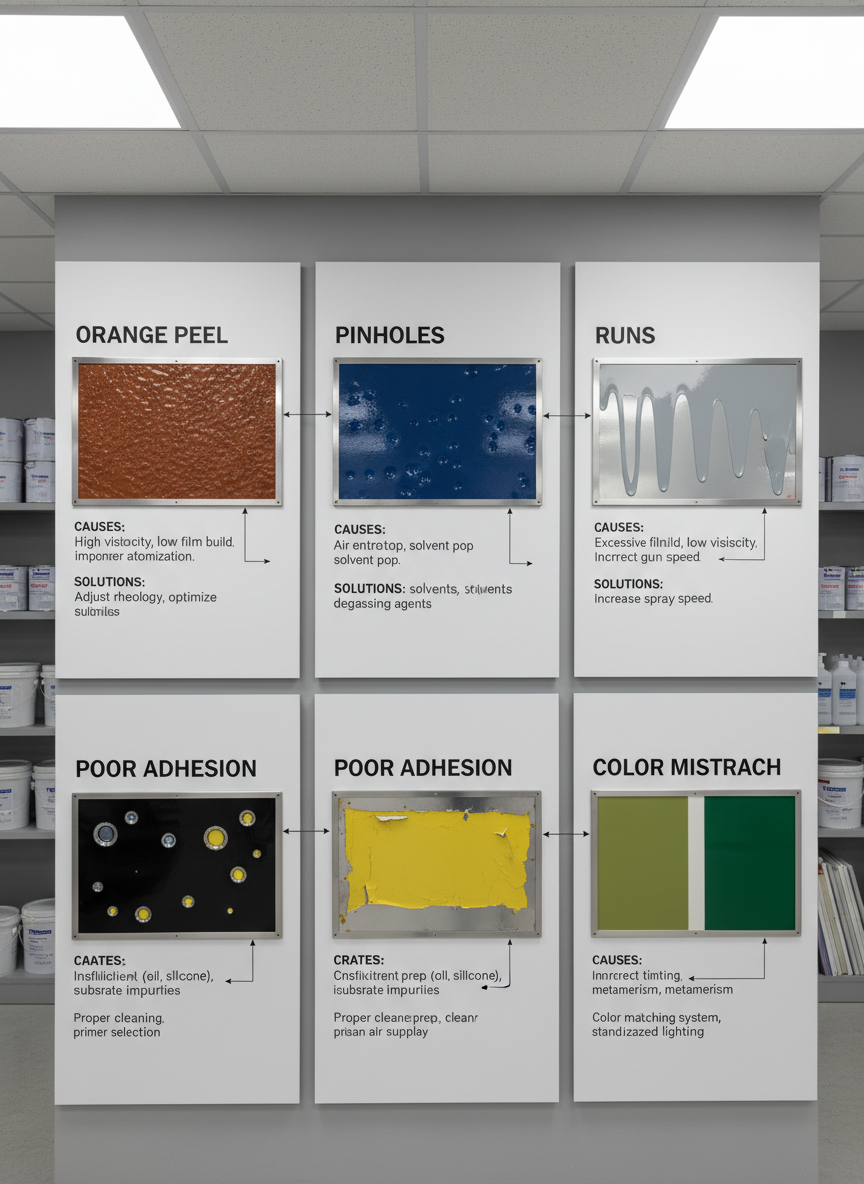

百曉生塗裝專注於材料理論與現場實務,提供問題診斷、實作訓練與技術顧問,協助工廠提升穩定性、產能與品質。

塗裝 技術 顧問

從材料理論到現場實務,提供系統化解決方案,協助塗裝工廠老闆以科學方法提升產能與品質,讓團隊更懂塗裝原理。

評論

Aya Nakamura

展示舊有工廠客戶對實務教學成效的回饋,提升轉換率。

Mateo García

展示舊有工廠客戶對實務教學成效的回饋,提升轉換率。

百曉生塗裝專注於材料理論與現場實務,提供問題診斷、實作訓練與技術顧問,協助工廠提升穩定性、產能與品質。

從材料理論到現場實務,提供系統化解決方案,協助塗裝工廠老闆以科學方法提升產能與品質,讓團隊更懂塗裝原理。

展示舊有工廠客戶對實務教學成效的回饋,提升轉換率。

展示舊有工廠客戶對實務教學成效的回饋,提升轉換率。